prices

Calculate sheet metal cutting price

teknow explains what components the price for a sheet metal cut consists of and gives tips for price optimization.

How is the price for a sheet metal cut calculated?

Since laser cuts are individually manufactured parts, the price is not a flat rate, but rather individual. There are three main components that make up the price:

Material price + machine time + fixed costs = sheet metal cutting price

You can find out exactly what these individual components are and how you can influence them below. But to give you a rough idea in advance: Most of the laser cuts that we produce are priced between €30 and €60. The only additional costs are the shipping costs. At the bottom of this page we have also prepared some practical examples that can give you a rough guide, as the material price in particular can change at short notice depending on the market situation.

Material price

For large parts or high quantities, the material price of the workpiece is often the largest component when calculating the price of a sheet metal cut. Depending on the type and amount of material used, this can be more or less important. Stainless steel, for example, is more expensive than mild steel – if a cheaper material is sufficient, replacing it can save significantly.

You can find a summary of all the materials offered by teknow at Materials.

Machine time

As the name suggests, machine time is calculated based on the amount of time our machines need to cut. Accordingly, complex laser cuts are more expensive than those that only require a few cuts. Workpieces whose contours consist of many short lines are comparatively complex. Workpieces with many cutouts also take longer to produce because the laser has to pierce the metal for each breakthrough. This is particularly true if the cutouts are small (e.g. in the area of the thickness of the sheet metal) – then the puncture must be made slowly with low power, otherwise the puncture crater will be larger than the cutout. The savings tip at this point is, if possible, to avoid structures that are too fine and small holes.

Under Manufacturing process you can find out which methods we use to individually produce your sheet metal cuts.

Fixed costs

As in every trade, we also have certain fixed costs that have to be covered. These include, among others:

- Checking the drawing, transferring it to the machine software and “nesting”. Your cut is arranged on the sheet metal plate together with orders from other sources in such a way that the best possible use of the material is achieved.

- Logistics: Place suitable sheet metal from the warehouse on the machine, collect the cuts and assign them to the orders, store the remaining sheet metal again.

- Administration

For small parts and small quantities, the fixed costs make up the largest proportion of the price of your sheet metal cutting. Example 3 shows you how you can save significantly if your parts are made of the same material and of the same thickness.

Shipping costs

The shipping costs are calculated based on the size and weight of the workpiece. We always ship in high-quality packages with DHL so that your individual laser part arrives safely.

Plan and realize sheet metal cutting at teknow

At teknow you can plan your laser cuts yourself using our online CAD program. Once the workpiece is finished, you will find out directly in the shopping cart how much it will cost you.

Examples of sheet metal cutting prices

Below we will show you three examples of real workpieces that we produced for our customers.

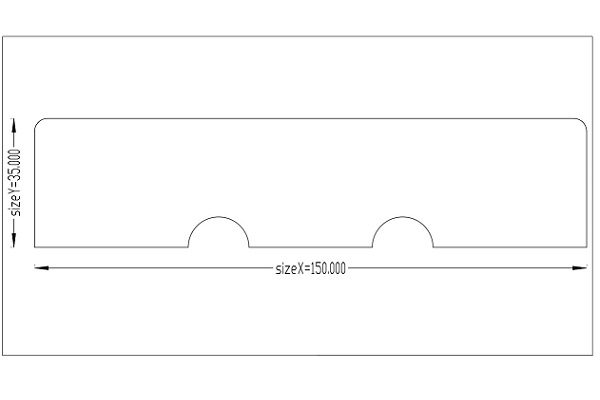

Example 1: Two-piece pipe cover for heating pipes

The two-part rosette is made of V2A stainless steel with a thickness of 3 mm. The parts are each 35 mm high and 150 mm wide. The cover fits standard heating pipes of Ø 16mm with a distance of 50mm.

This workpiece costs €27.90 as a single part. Two pieces cost €16.00 each, with 50 pieces the cost is only €4.57 each. (Gross, plus shipping)

How does the price change with different material or thickness?

In the same material, stainless steel V2A, but with a thickness of 1 mm, a single part costs €25.95. Two pieces cost €14.05 each, for 50 pieces it costs €2.63 each.

In the inexpensive steel DC01 material, 3 mm thick, a single part costs €26.54. Two pieces cost €14.64 each, 50 pieces cost €3.21 each.

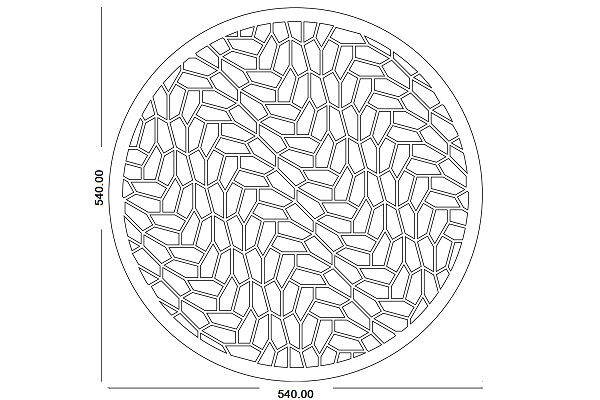

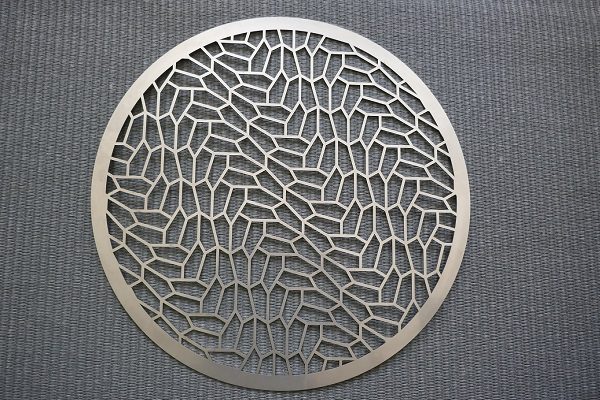

Example 2: Grill grate

Grill grate made of 2.5 mm stainless steel with a diameter of 54 cm. This workpiece requires a large number of cutouts, which account for the majority of the costs.

This workpiece costs €157.64 as a single part. For 50 pieces the cost is €134.32 each. (Gross, plus shipping). The material is not a significant cost factor, and for the intended purpose – contact with food – there is no cheaper material available.

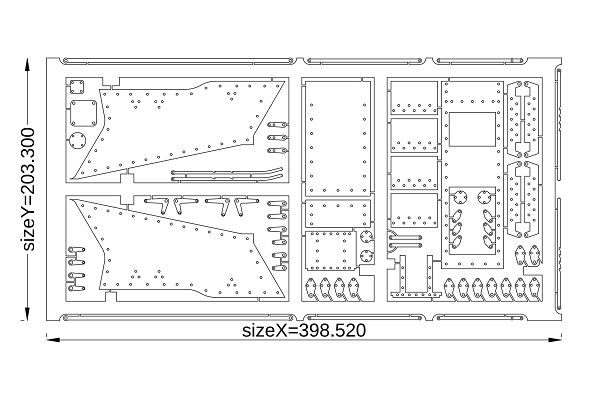

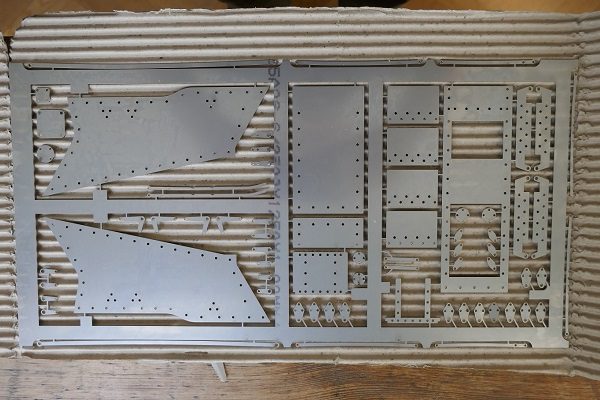

Example 3: Model components arranged in a grid

Model components made of 1mm stainless steel. Here, many different parts, each in small quantities, were joined together using webs to form a single blank. Otherwise, fixed costs would be incurred once for each different part, which would make production very expensive. The individual parts are later cut out of the grid with pliers and the base is sanded off.

This workpiece costs €80.72 as a single part. Here too, the material is not a significant cost factor, but rather the cutting time due to the many small structures and holes.