This surface finish is also known as a scaled surface. Spark protection plates are available here as individual cut pieces with any contour – there is also a solution for complicated installation geometries.

Why do you need a spark protection plate?

If the floor on which the fireplace or stove is located is not fireproof, a non-combustible base is required. This prevents sparks falling out when adding firewood from starting a fire. A nice material for such a base is untreated black plate. With the teknow designer you can cut the sheet metal individually, with any contour and cutouts, e.g. for the air supply. This means that the sheet metal can be precisely adjusted even in difficult cases, such as walls and projections that are not at right angles.

What is Black plate?

Black plate is a non-descaled heavy steel plate (from 3 mm thick). The “scale”, the iron oxide on the surface, is created when the glowing sheet is rolled. A lively gray to blue surface color is created. Each sheet has an individual color structure. The surface has a metallic shimmer rather than a shine.

The sheet metal may have slight scratches due to transport, production and cutting, especially on the underside due to being placed on the laser machine. It is therefore important to create the drawing correctly. Since the surface color is a by-product of the production process, a guarantee for a specific appearance is not possible.

That is how it works:

The spark protection plate must cover the areas at risk of fire by 300 mm on the side and 500 mm on the opening side in front of the oven. If the oven can be rotated, this must be taken into account accordingly. If in doubt, ask the chimney sweep, who will also inspect and accept the system at the end.

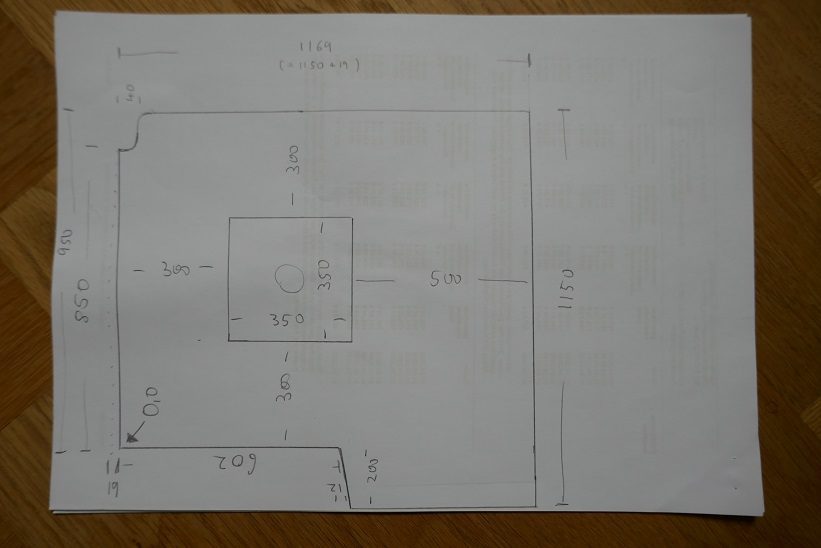

Then it’s best to make a hand sketch of the plate. To do this, select a suitable corner as the zero point and enter the dimensions from there on in mm. In most cases this is very easy. Here is an example of a more difficult case.

This is what the corner looks like. The walls are not exactly at right angles. The oven has a footprint of 350 x 350 mm², so the plate would have to be 950 mm wide. The wall at the top of the picture is only 850 mm long – so you have to avoid the base of the door frame.

First we carefully measure the corner and make a paper sketch. I used the back right corner as the zero point. All dimensions are given in mm.

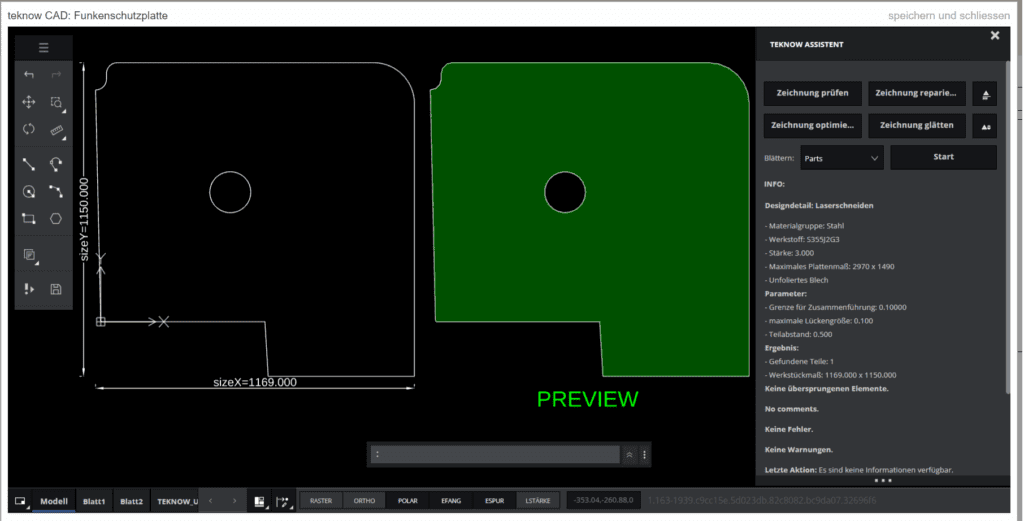

Then you transfer the sketch to teknow CAD. How to do this is explained in detail in the help and videos.

Note: When selecting the material, select one of the scaled surface variants. The sheets in the same material are also available as pickled and oiled – then the scale layer is removed and the surface is bare.

The view is rotated 180° compared to the images above because the origin of the drawing area is at the bottom left.

After delivery:

Now you have a self-designed spark protection plate with an individual surface color. So that you can enjoy the plate for a long time, we recommend that you keep a few things in mind. Black plate rusts when it gets wet. It can be used indoors untreated as long as it does not come into contact with water. After delivery, you should check the edges and, if necessary, round them with some sandpaper, then clean the sheet once – simply wipe with a sponge or cloth, warm water and dishwashing liquid. Then dry the sheet thoroughly, especially the cut edges. The sheet metal can be oiled or varnished, perhaps adapted to the floor material, such as oiled or varnished parquet. Apply the oil (e.g. linseed oil, Ballistol) very thinly and allow to dry. Can be painted with an acrylic clear coat for metals (semi-matt, not water-based). The painted surface will be more sensitive to glowing pieces of coal than the oiled one.