Plate frames, frame stretchers and other parts for locomotive models can be ideally produced using laser cutting. Of course, what has been said applies just as much to other types of drive, such as battery-powered models.

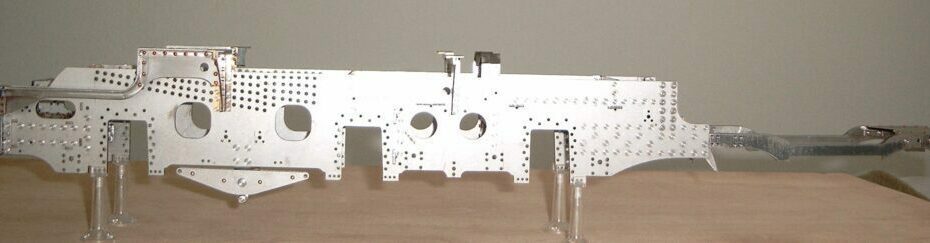

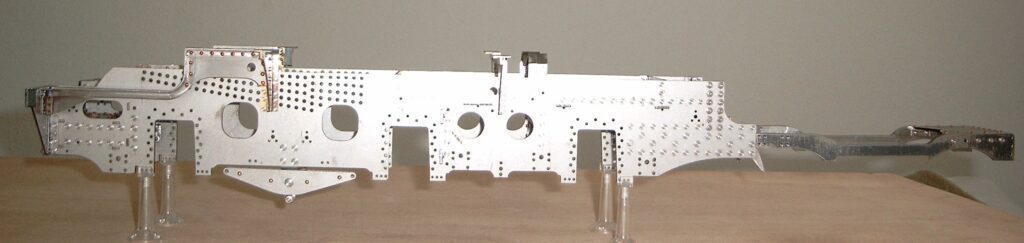

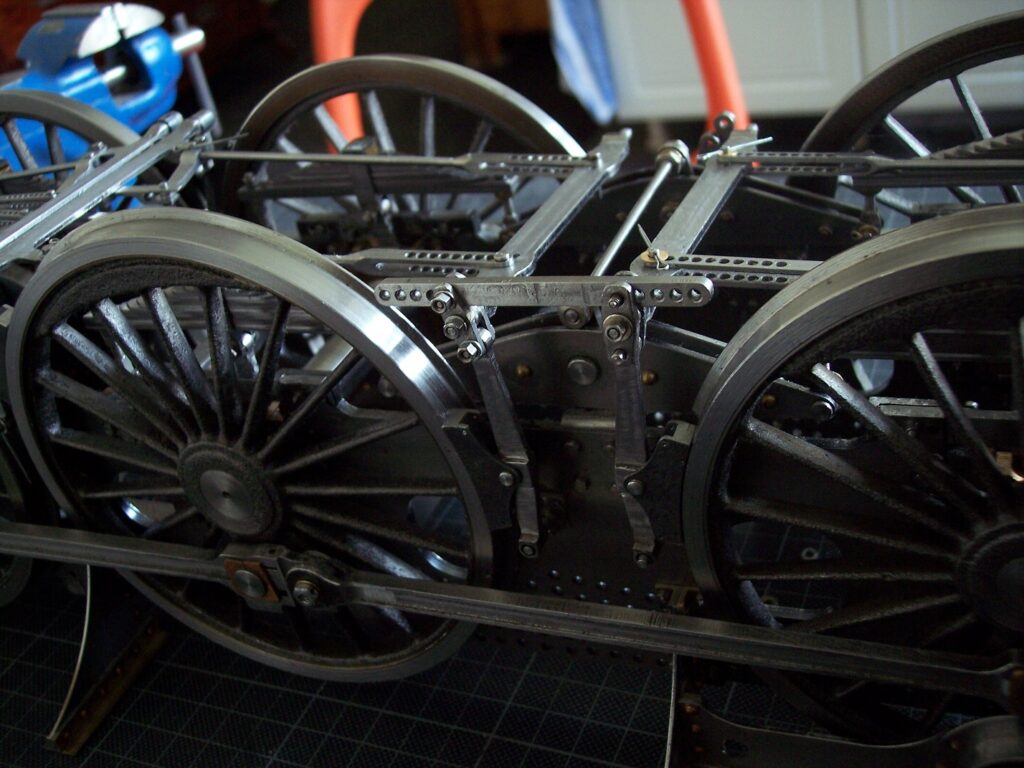

The example shows the plate frame of a model pr. S 10 in 1:16 scale. All holes were lasered out at the same time, along with tenons and slots in some places for precise alignment of the plates. The frame is 3 mm thick, the shoeed bar frame consists of 10 mm thick sheet metal that has been further processed by milling. The curved beams, the consoles and the balancing levers were also created using laser parts.

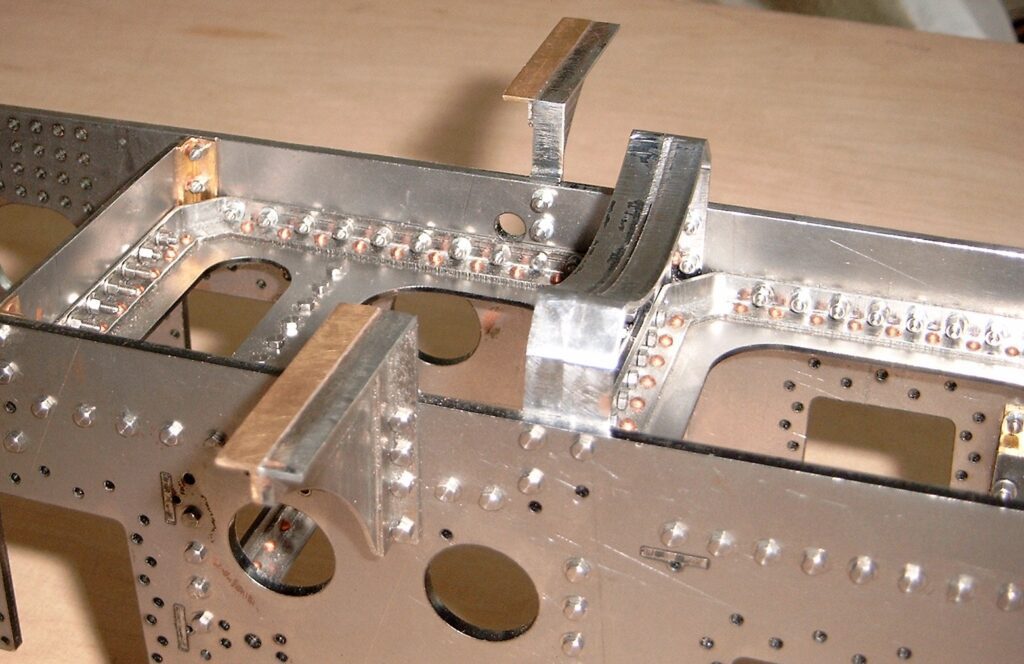

The detailed image shows the frame stretchers using sheets that are riveted and screwed together using angle frames.

The blanks for the angle frames and the boiler support are made of 6 mm sheet metal, and the angles were then made by milling. Parts of the same thickness were each grouped together by webs. This is usually cheaper. For parts that are to be further processed by milling, this simplifies clamping if the arrangement is appropriate.

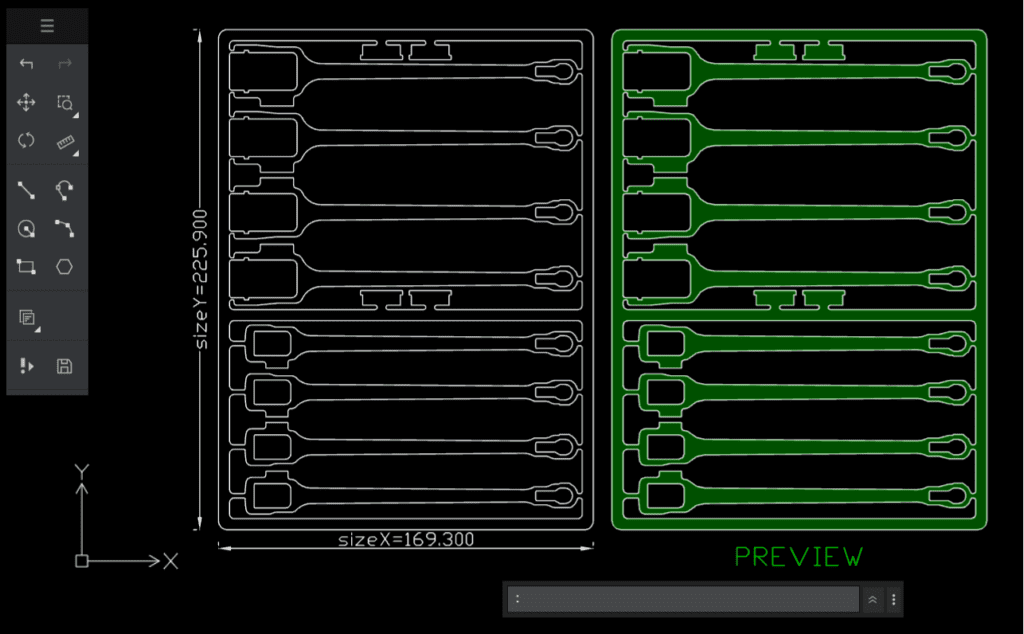

The drawing shows the outer and inner connecting rods combined into a block, as well as the locks of the inner connecting rod heads.

The blanks for many other parts of a live steam model can also be easily produced using laser cutting. Here are some examples.

Left: The blanks for the wheel tires are made of 10 mm steel.

Middle: The blanks for the drive and coupling rods as well as the valve gear parts can be arranged in a grid so that they are easier to clamp on the milling machine for finishing. The picture shows the assembled combination levers being finished on the milling machine.

Right: Brake blocks, brake levers and compensation beams based on laser blanks.